Hardcrome Plating

Our is the First Company in Chennai Using Advanced Technology Hardchrome Plating for Custom Plating.

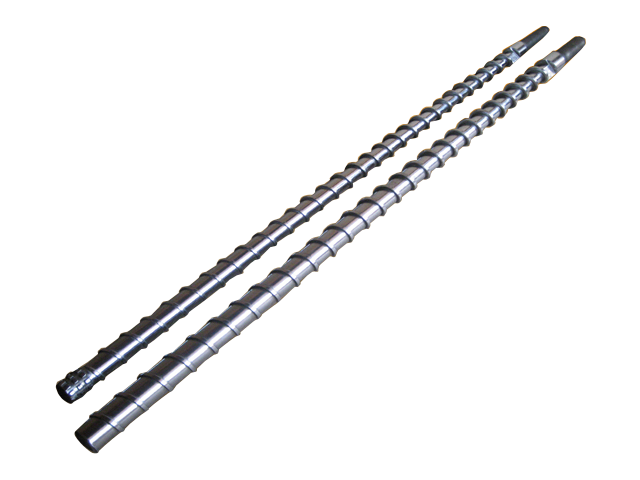

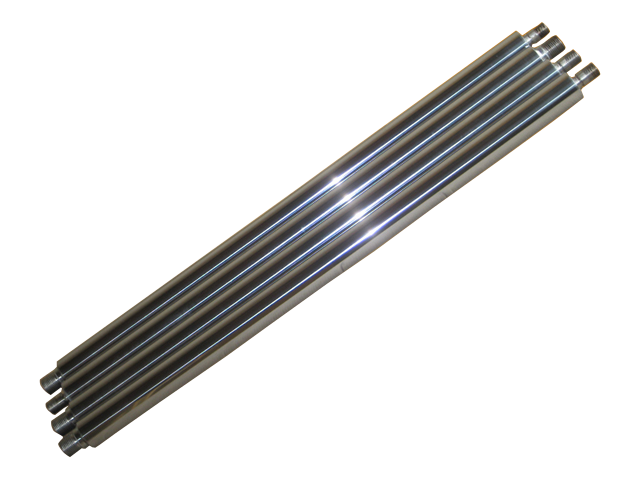

We undertake mirror finish HARDCHROME Plating on Hydraulic Shafts & Rams, Plastics, Rubber, PVC moulds, Extruder screws. Barrels, Tie bars, Leather tanning Machine shaving rollers, Chemical Plungers, printing rollers, Lamination rollers, Reclamation of worn out parts etc & Many more in both ferrous and non ferrous metals.

Job Capacity

- 60" x 30" x 30" [moulds & dies]

- Dia 1500 mm x 6 meters length rollers and shafts

- Both ID and OD plating done

Job weight capacity: 7 Tonnes

- Recommended thickness 0.02 mm in which the plating will faithfully highlight the condition of steel

- Maximum crack free plating thickness of 800 microns

- Delivery on time

- Urgent delivery on prior schedule arrangements

Advantages of Hardchrome

- Very good adhesion to base material

- Improves and maintains surface finish

- Close dimension control after coating

- Increases hardness of surface to 68-72 R

- Low coefficient of friction

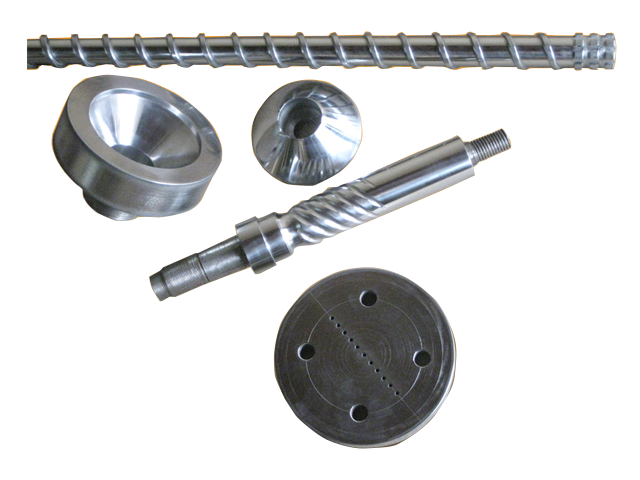

Precision Machining

Machining & Manufacturing of all kinds of engg components as per drawing using both conventional & latest CNC machines.

Grinding

Center less grinding & cylindrical grinding before and after Hard chrome on rollers and shafts up to dia 600x3m length.

Polishing

Wide range of polishing machines up to 25000 r.p.m are employed to achieve mirror finishing on Hard chrome surface on any profiles.